A New Era in Canister Analysis Has Arrived

Entech has been developing new technology to improve canister monitoring for over three decades, and our latest announcement may be the greatest single advancement in canister analysis to date. The SkyCan™ Autosampler represents a giant leap forward in bringing today’s canister laboratory inline with other GCMS laboratories, by placing canister samples above the GCMS, maximally close to the sample preconcentrator prior to analysis. The SkyCan Autosampler improves system integrity by removing the sample-to-sample variability present in multi-inlet rotary stream select valve autosamplers. Stream select autosamplers are further compromised by the long residence times of sampling in each line, making it difficult to achieve low and consistent background levels after exposure to higher concentration samples. With the lowering of allowable background levels (e.g. EPA Methods TO-15A and 327), autosamplers that rely on rotary valves may no longer be capable of consistently achieving the extremely low blank levels required to provide sample analysis at parts per trillion detection limits. Imagine the challenge of demonstrating blank levels for each individual line in multi-inlet autosamplers, every single day. The SkyCan simplifies this by utilizing a single inlet that requires only one blank check. This single-inlet design, coupled with vacuum cleaning of the inlet between samples, streamlines your analysis process and minimizes the risk of contamination.

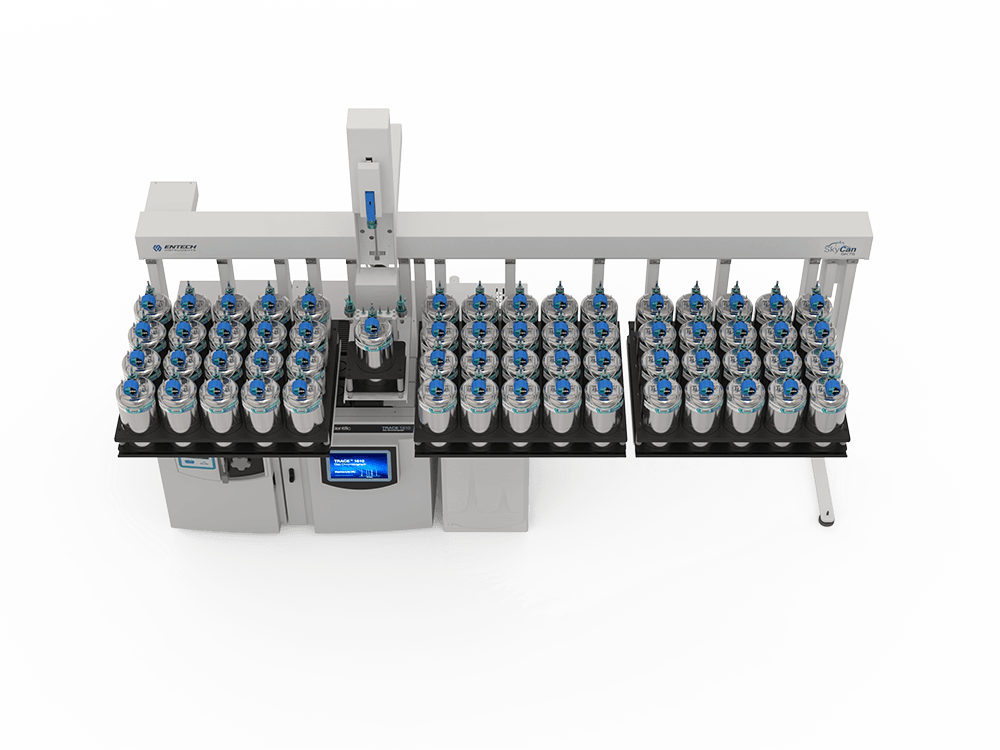

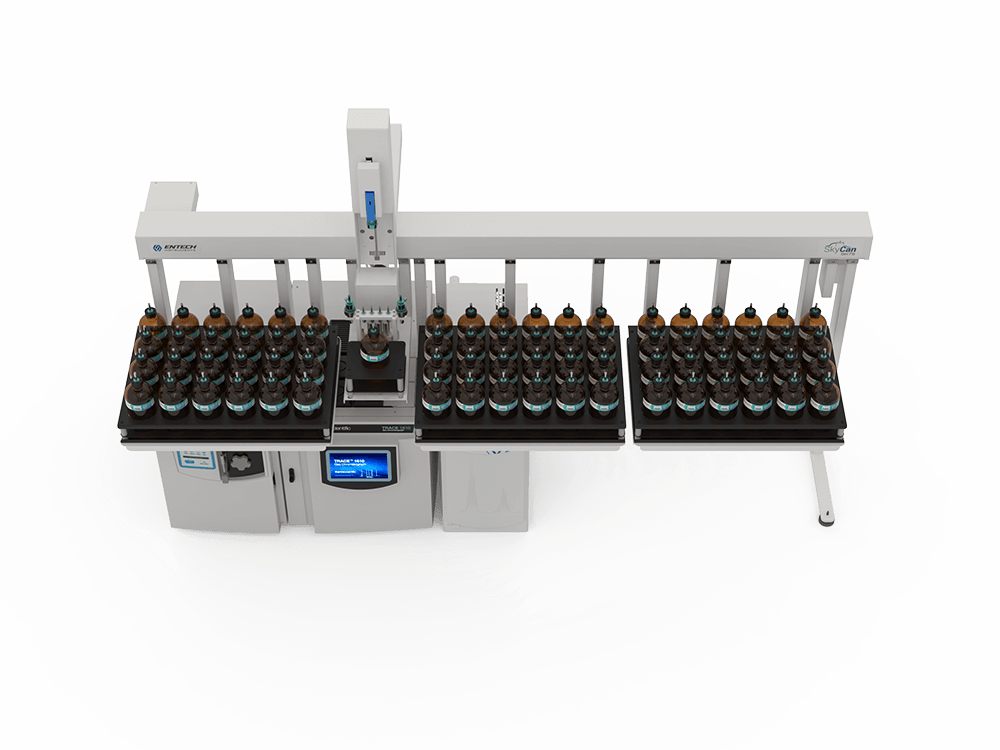

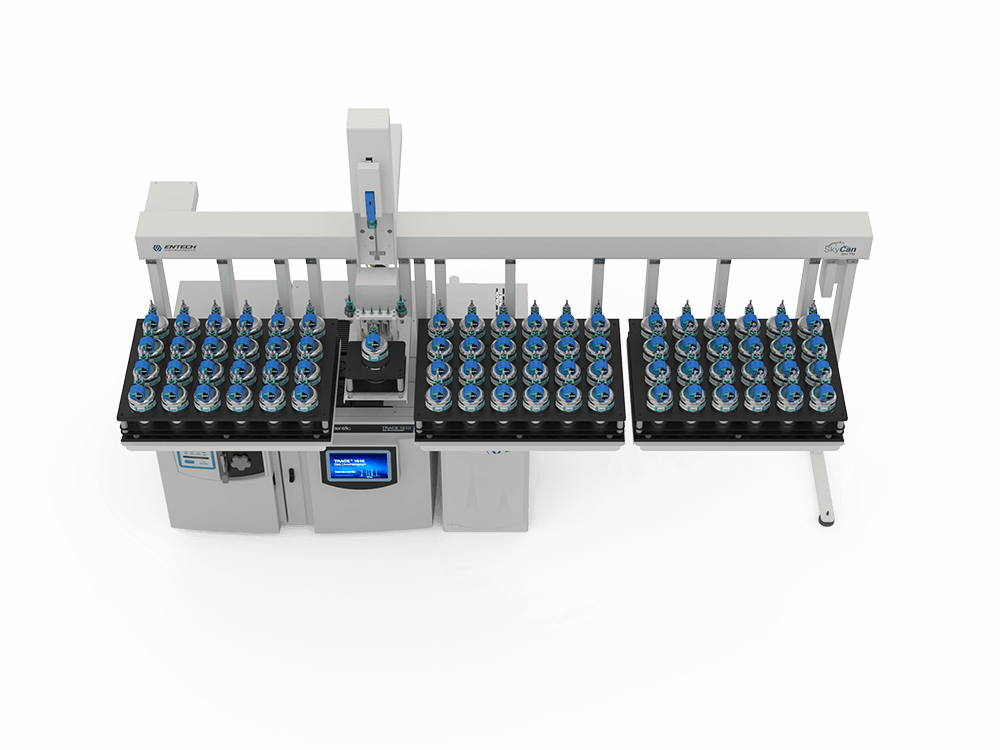

With the SkyCan you enjoy all of the advantages of a robotic system: a single inlet, short sample exposure times, vacuum cleaning between samples, reliable blank levels, connection to cans only at the time of sampling, exceptional resistance to contamination, and no risk of cross contamination caused by leaky stream select valve rotors, among other advantages. We urge you to free ourselves from the burden of cluttered lab spaces, reclaim your valuable bench space, improve shipping and can cleaning efficiency—all with just one strategy… Take to the Sky!

Next Generation Features to Put your Lab Ahead of the Competition

No bench or floor space required for samples. All are placed above the GCMS, the preconcentrator, and the data system.

Available in a 40” rail (SK40) or a 75” rail (SK75), based on system throughput requirements.

Fully automated rail system with magnetic sensing of tray and Canister Analysis platform positions

Trays are available to handle all Entech canister sizes 2.5L and smaller, as well as 500cc and 1L Bottle-Vacs

Connects to the 7200A or 7200CTS Autosampler #1 inlet, leaving AS #2 and AS #3 available for the 7016D 6L canister autosamplers.

Analyze up to 36 of Entech’s new 2.5L ambient sampling canisters (15 on the SK40 SkyCan™), providing ample volume to achieve today’s stringent detection limits, while also reducing shipping and storage costs.

Heated transfer line length to preconcentrator only 2' long to reduce surface interactions, improving run to run consistency.

Inlet transfer line is vacuum cleaned immediately after exposure to the sample.

SkyScreen and SkyLoop options use a completely different flow path to perform high throughput screening or quantitative loop injection with zero chance of preconcentrator contamination.

Fully integrated into Entech's latest preconcentrator control software

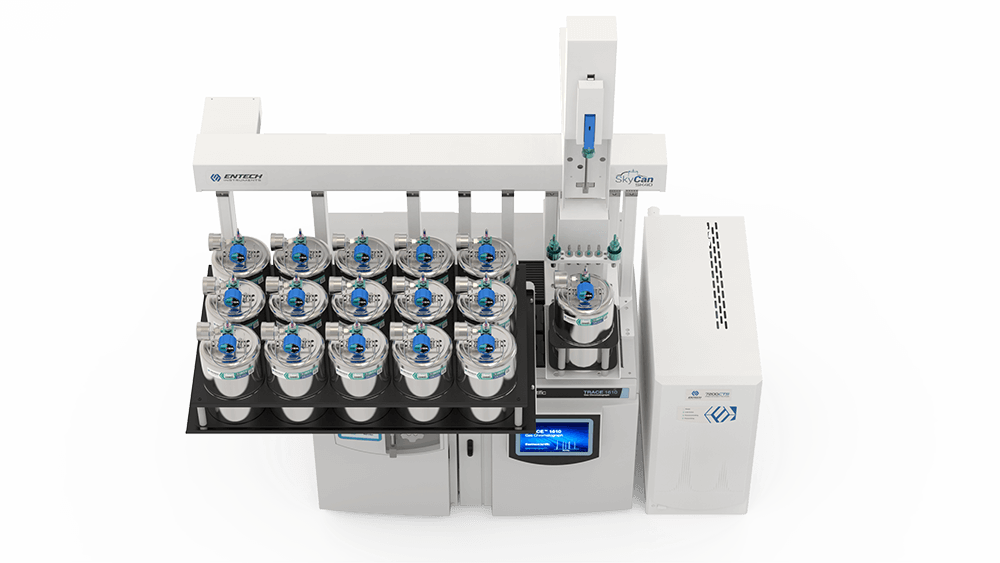

SkyCan 40” - SK40

The SK40 is the ideal replacement for the Entech 7032XX rotary valve systems. Unlike the 7032XX that used 21 different inlet lines at potentially 21 different background levels, the SK40 uses only 1 sample inlet that is vacuum cleaned between samples to provide incredibly low carryover from run to run. Like it’s larger SK75 cousin, the SK40 can use the SkyScreen module to pre-test samples to ensure they will not contaminate the 7200CTS or 7200A preconcentrators, using a very fast 8-10 minute injection to injection screening process. The SK40 can connect to a cryogen based 7200A, or a cryogen-free 7200CTS, along with up to two 7016D towers to truly optimize flexibility and throughput.

SK40 Canister Configurations

(15) 2.5L Canisters

1x 15-Position Tray

TRAY PN: SK-LT525-015

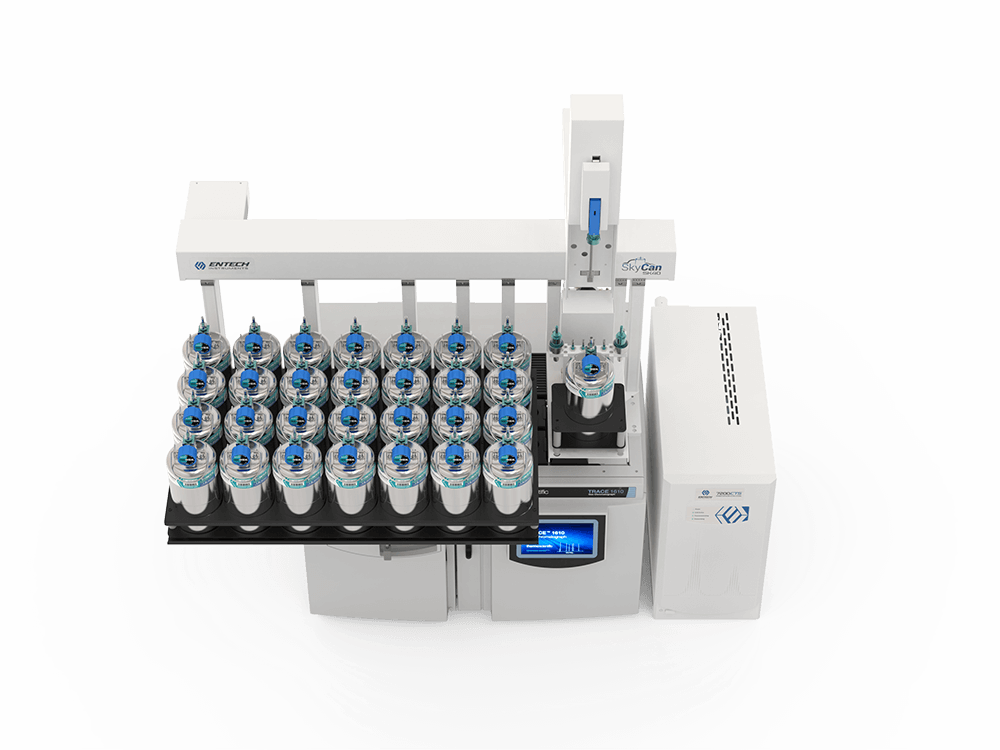

(28) 1-1.4L MiniCans

1x 28-Position Tray

TRAY PN: SK-LT405-028

(28) 1L Bottle-Vacs

1x 28-Position Tray

TRAY PN: SK-LTBV383-028

(32) 500cc Bottle-Vacs

1x 32-Position Tray

TRAY PN: SK-LTBV302-032

(32) 450-600mL MiniCans

1x 32-Position Tray

TRAY PN: SK-LT280-032

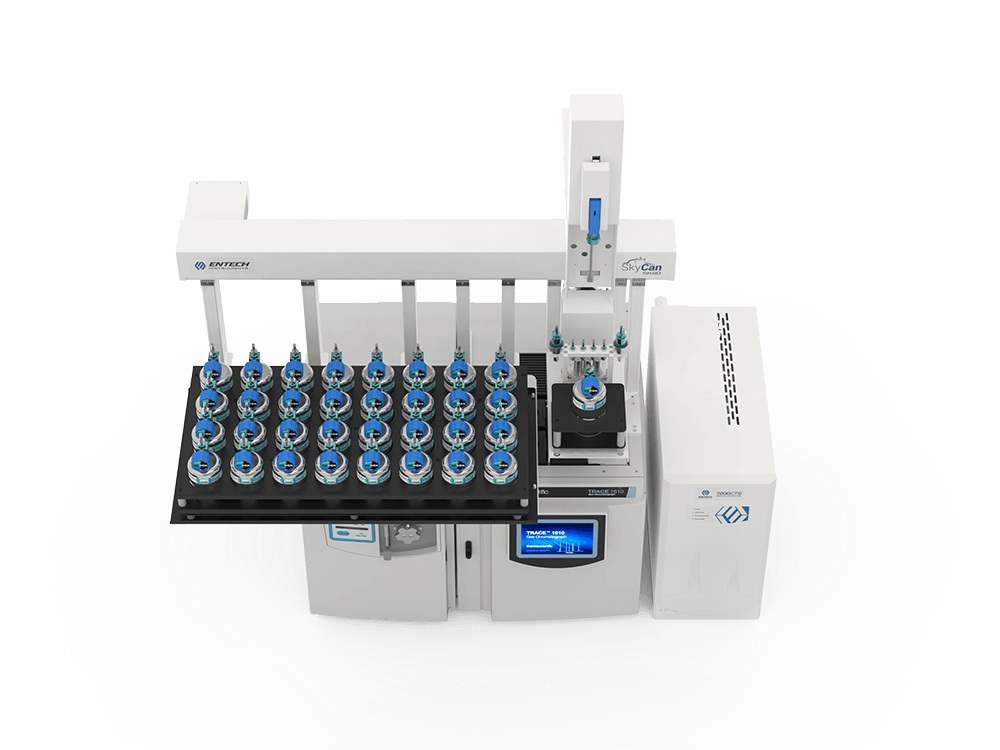

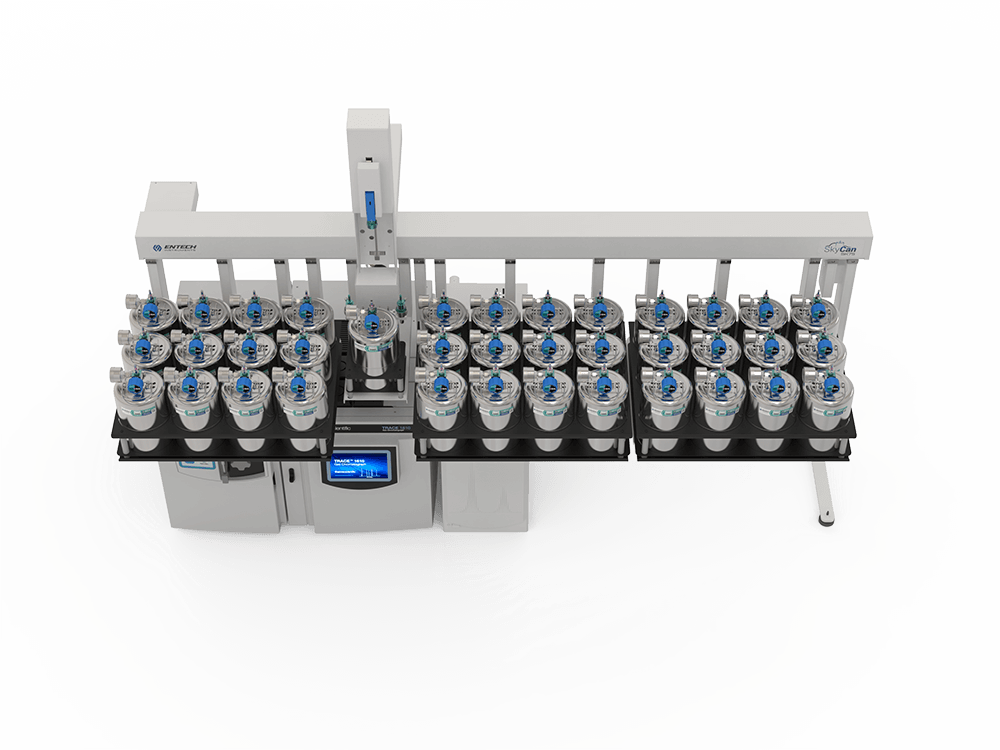

SkyCan 75” - SK75

With an impressive span of 75”, the SK75 provides the ultimate solution for maximum unattended TO-15/TO-15A analysis. Analyze 36 of the new Entech 2.5L ambient sampling canisters, which have plenty of sample to reach TO-15A detection limit requirements. The SK75 is also ideal for the analysis of 1-1.4L canisters, as well as 0.5-1L Bottle-Vacs. Secured by a mounting system compatible with Agilent, Thermo or Shimadzu GCMS combinations, the SK75 lives above the GCMS, taking zero bench space, to allow optimum sample throughput in even the most cramped laboratories.

The SK75 may also utilize the novel Sky Screen™ module to pre-test samples to ensure they will not contaminate a connected 7200CTS or 7200A preconcentrator, using a very fast 8-10 minutes screening process. If approximate concentrations of canisters or Bottle-Vacs are unknown, it is far safer to screen them before preconcentrating in a trace level preconcentrator. This is easily accomplished with the Sky Screen module, which can inject a 0.1, 0.25, or 1cc loop into the GC carrier gas for delivery to the GC or GCMS. If the GC column is maintained at 150C, most VOCs elute in just 3-5 minutes, with zero wait time for the GC oven to get ready for the next injection. No need to risk having a bad day by accidently concentrating a high PPM level sample. The Sky Screen module totally removes this risk, while the vacuum on the Source Level Sampling Inlet makes carryover even at the high PPM level a thing of the past.

SK75 Canister Configurations

(36) 2.5L Canisters

3x 12-Position Trays

TRAY PN: SK-ST525-012

(60) 1-1.4L MiniCans

3x 20-Position Trays

TRAY PN: SK-ST405-020

(60) 1L Bottle-Vacs

3x 20-Position Trays

TRAY PN: SK-STBV383-020

(72) 500cc Bottle-Vacs

3x 24-Position Trays

TRAY PN: SK-STBV302-024

(72) 450-600mL MiniCans

3x 24-Position Trays

TRAY PN: SK-ST280-024

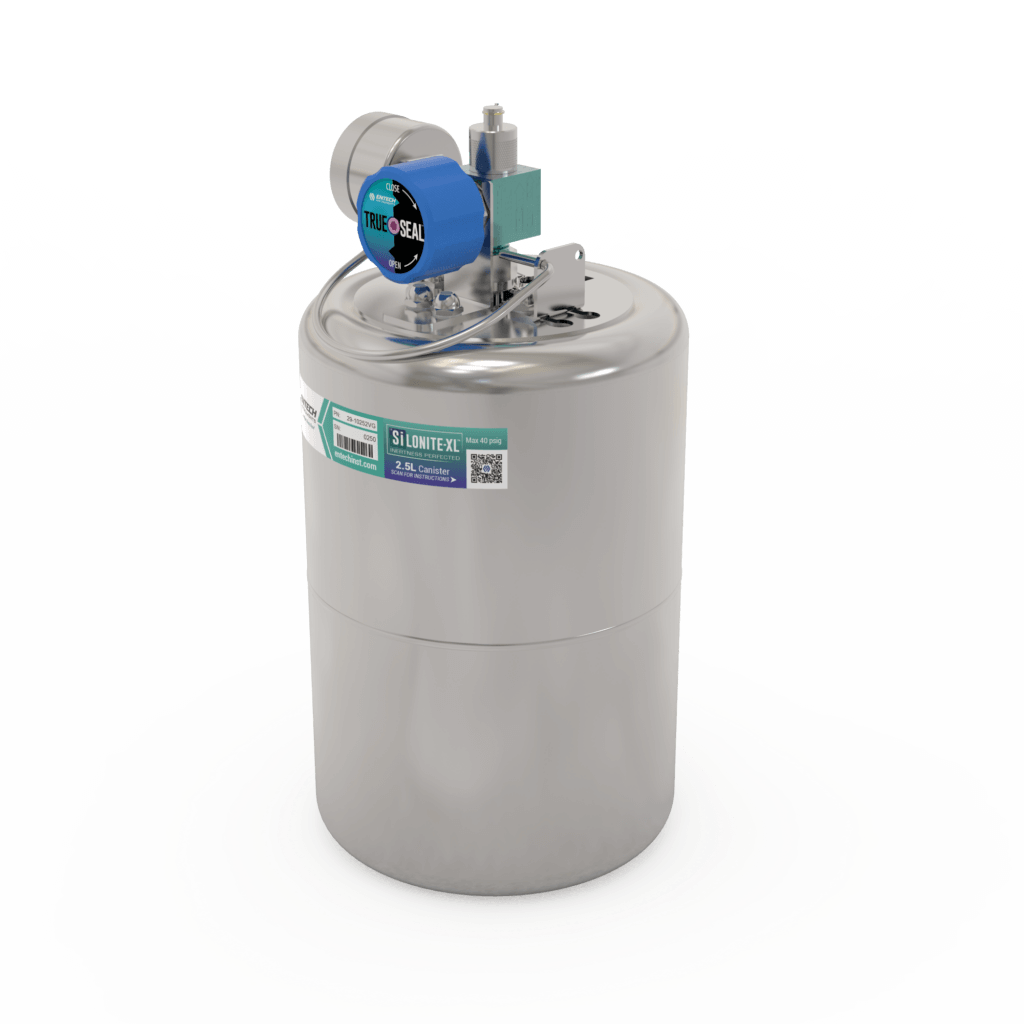

The Ultimate TO-15A Solution: SkyCan + 2.5L Silonite-XL Canister

With the latest introduction of the US EPA Method TO-15A, labs must now prove both cleanliness down to 0.02 PPB, and sub-PPB level stability in EVERY canister, for 2 weeks to 30 days depending on quoted holding times by the lab. Given that numerous 6L canisters have been heavily utilized over the past 35 years, it is highly probable that a significant portion of them will not satisfy the new, rigorous requirements. What better time to look at changing to a new canister geometry that is optimized for today, not 35 years ago when TO-14 first appeared. The new Entech 2.5L Silonite-XL Canister is just such a technology, as it takes advantage of improved GCMS sensitivity which has increased over 100x in the past 35 years. With the 250mL sample size recommended in Method TO-15A, a 6L sample container is no longer needed. The more compact Entech 2.5L Silonite-XL canister provides plenty of sample for multiple analyses, occupies less space in the lab, and up to nine can ship in the same box used to ship just four 6L canisters.

Get Product Pricing, Promotions, App Notes & More