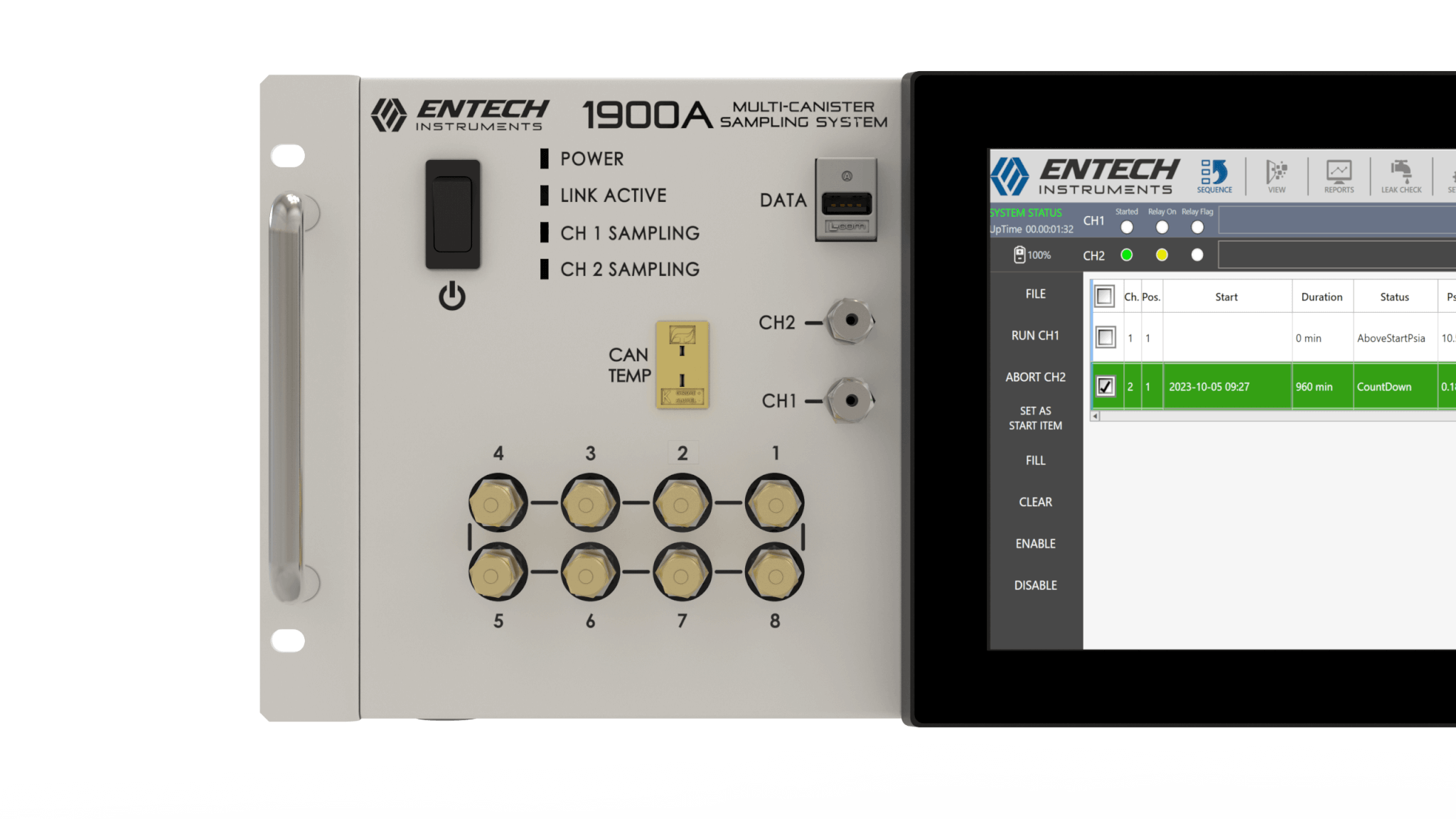

1900A Dual Channel Canister Sampler

Precision, Reliability, and Advanced Contamination Control

The 1900A is a 3rd generation vacuum canister sampling system, dramatically improving upon previous designs to deliver the most reliable and accurate remote VOC air sampling available today. Engineered to meet the highest environmental standards, including US EPA Method TO15A, the 1900A simplifies canister filling while significantly reducing contamination risks. With enhanced automation and precision, this advanced sampler ensures that even complex, multi-canister sampling events are handled efficiently and consistently.

Key Features

Superior Sampling Accuracy:

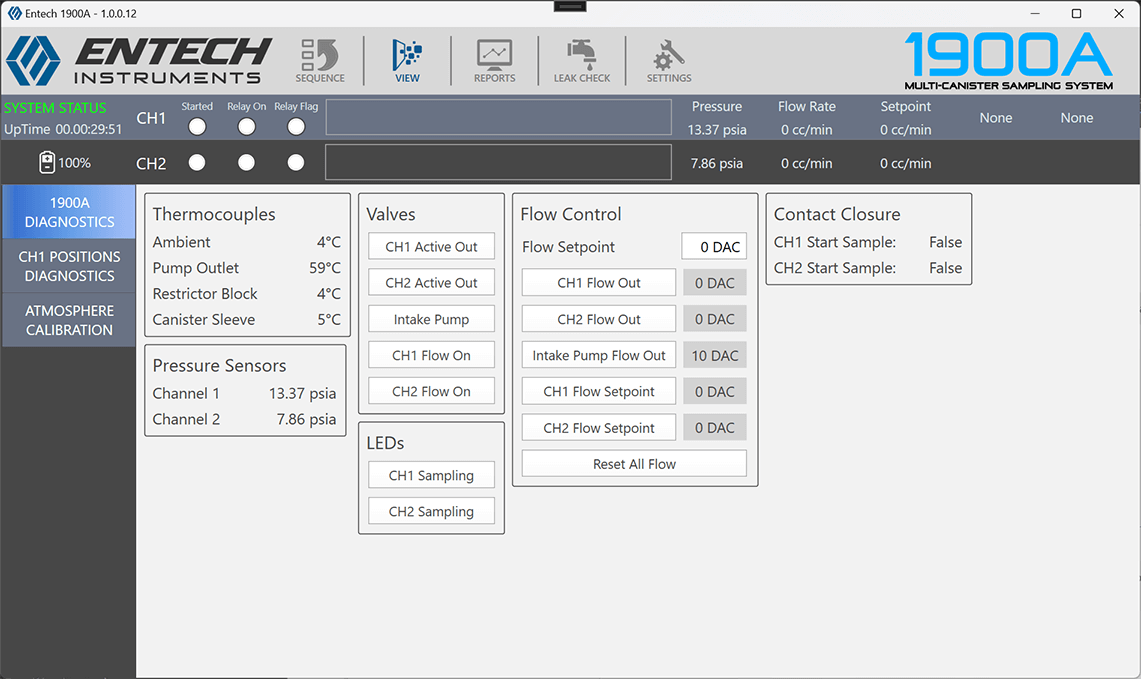

Monitors temperature-compensated pressure to maintain a consistent canister fill rate, achieving less than 1% sampling error

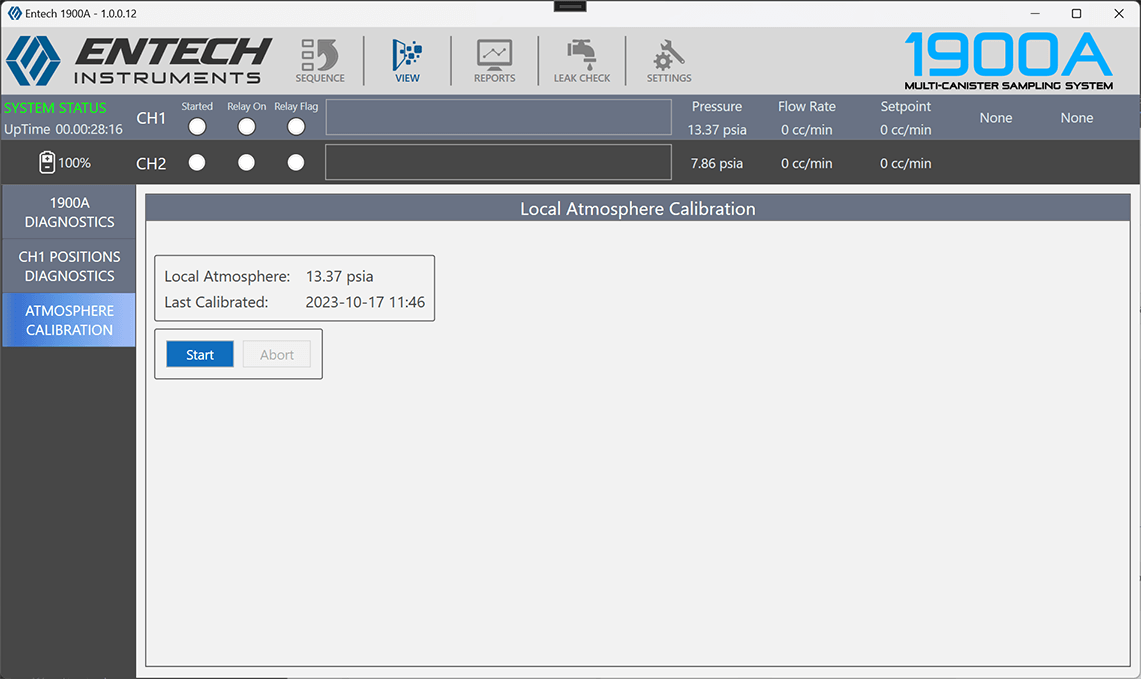

Local Atmospheric Pressure Compensation:

Most canister methods allow filling to no closer than 2” Hg of atmospheric pressure. The 1900A determines local atmospheric pressure before sampling, so canister filling up to within 2-3” Hg of local atmospheric pressure occurs every time.

Simplified Flow Path:

Streamlined internal design reduces the number of seals and connections, minimizing potential leak points and simplifying maintenance.

Minimized Contamination:

Silonite™-coated pathways reduce chemical reactions and outgassing, preserving sample integrity. A large Silonite-coated prefilter at the intake prevents aerosol and particulate contamination.

User-Friendly Automation:

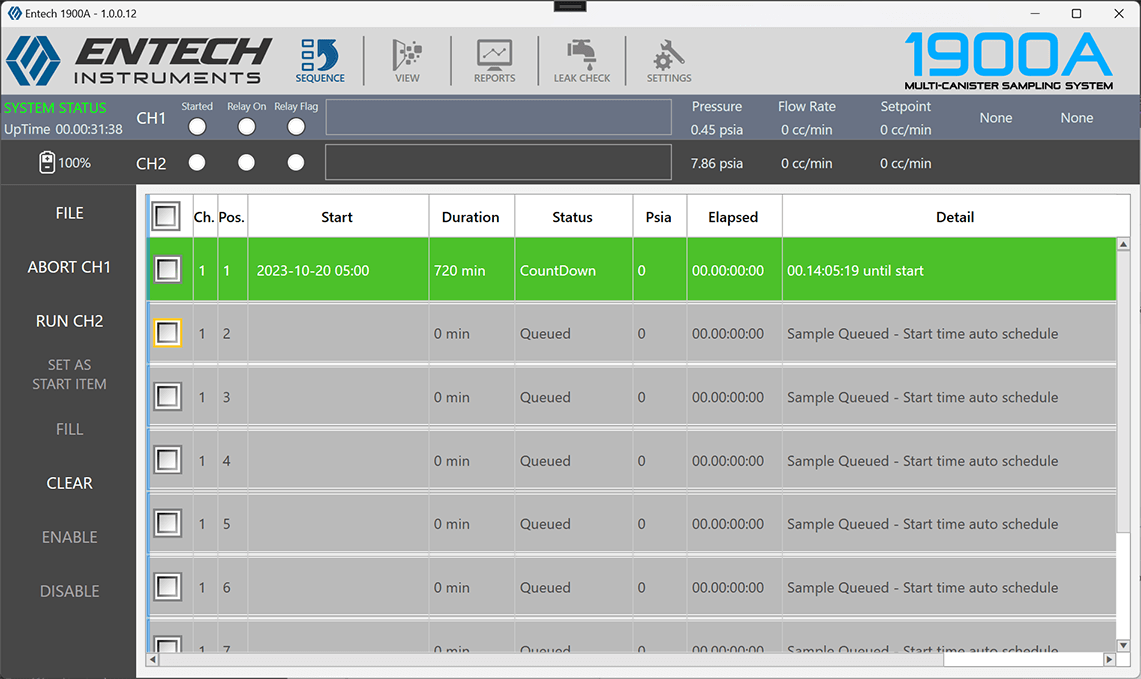

Independent channels (CH1 and CH2) support local, remote, and pre-scheduled sampling, with CH2 offering a 24-hour sampling option every six days for specific monitoring programs.

Scalable Sampling Capacity:

Expandable with 8- and 16-position modules, enabling continuous or event-driven sampling without site visits.

Dual Channel System for Project Compatibility

Central to the 1900A’s design is its Dual Independent Fill Channels – CH1 and CH2. The channels provide a diverse array of triggering options, encompassing remote, local, and pre-scheduled modes. CH2 has an additional mode where it automatically advances the scheduling to provide a 24 hour canister collection “once every 6-days” to meet NATTS and other US EPA monitoring programs. This flexibility ensures that professionals can customize their sampling approach to fit the exact requirements of each study.

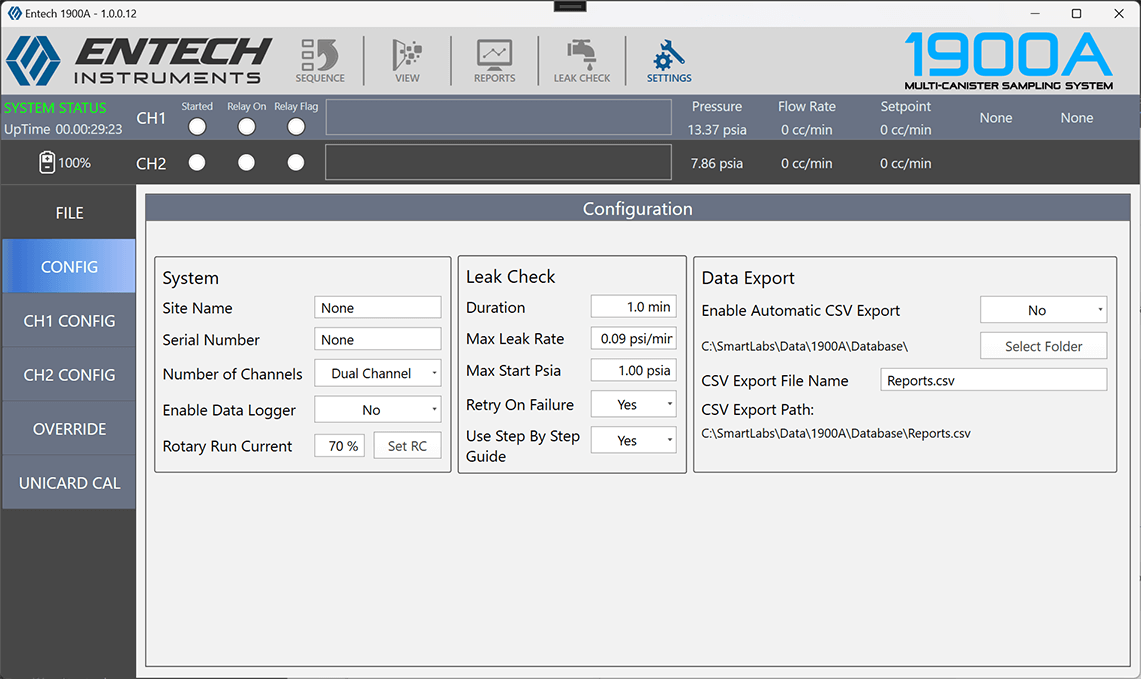

User-Friendly Experience & Advanced Compatibility

The 1900A is remarkably user friendly. Its intuitive software offers the ability to schedule sampling events up to weeks in advance. Software features in the 1900A meet or exceed the requirements of EPA Method TO-14A, TO-15, TO-15LL, TO-15A, ASTM D5466, and China Method HJ759-2023. The 1900A features a high-flow sample inlet using a 1-5 L/min variable flow pump to quickly bring fresh sample to the sampling inlets. The pump is turned off when not sampling to reduce the unnecessary buildup of heavier semi-volatile compounds on the inlet filter over time. Canister connections are made using 1/8” Silonite coated stainless steel tubing, through one of Entech’s unique, leak-tight solutions including Nickel ferrule compression fittings, FlowMate Adapters, or Micro QT Valves.

Industrial Windows Controller with Intuitive User Interface:

CH1 and CH2 outputs to canisters, with internal modules available to fill up to 8 canisters through CH1. A thermocouple input allows temperature compensation of the canister pressure to improve mass fill rate accuracy.

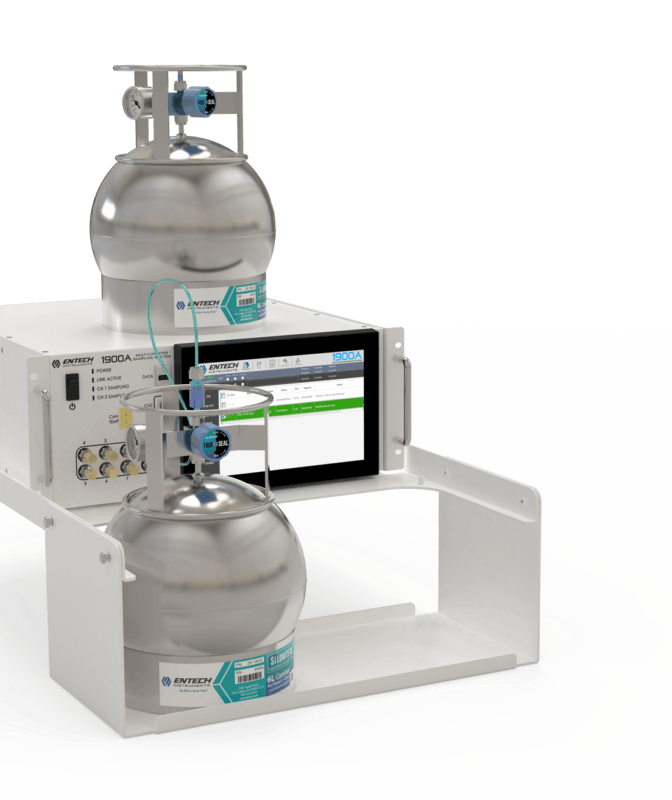

8-Channel Expansion Option Supporting Multiple “Event” Sampling or Continuous Monitoring

The 1900A offers multiple options for increasing the sampling capacity of the system. CH1 can incorporate an 8-Channel expansion option within the 1900A, with 8 output ports and a tray to hold canisters when multiple sampling events are needed. In addition, the advanced flow control of the 1900A allows a 24 hour fill time into 1L to 6L canisters, allowing 7 canisters a week to be collected when performing continuous monitoring, with an 8th position to allow scheduling options for sample retrieval.

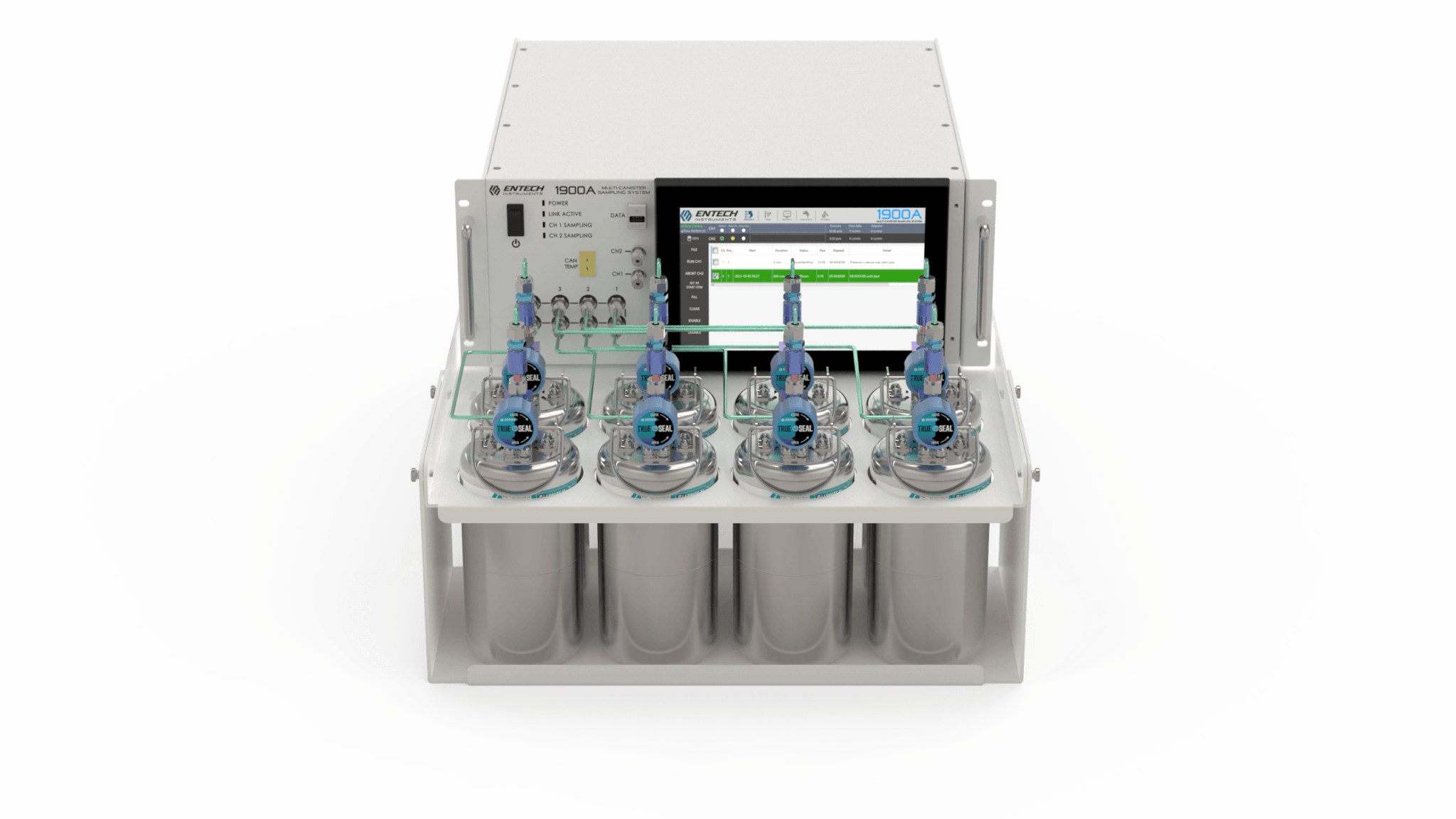

Two 8-Channel Options are Available

8-Position Rotary Valve (PN: 1900A-EXPAND8-RV) – Chromatographic Grade Stream Select Valve module with individual pressure sensors for each canister for constant local or remote evaluation of canister vacuum levels in every canister.

8-Position Micro DC Solenoid Module (PN: 1900A-EXPAND8-MDCV) – 8 Extremely small solenoid valve just over ¼” in diameter allow access to canister utilizing a unique “Cool” activation technique that keeps valves from heating up, allowing trace level sample collection without outgassing. Allows 2 canisters to be filled at once to create duplicates as needed for QA purposes.

Continuous Monitoring using 1 or 2 1916A, 16 Position Expansion Modules

Expand your capacity for collecting canister samples in continuous monitoring applications by integrating one or two 1916A, 16-position expansion modules into your setup. This addition allows for the collection of 24-hour samples daily for an entire month without the need for site visits. Alternatively, opt for higher resolution sampling by collecting every 8 hours, enabling the accumulation of 21 samples each week. This frequent sampling helps pinpoint specific times in the diurnal cycle when VOC concentrations peak. For an even finer temporal resolution, you can configure the system to collect samples every 3 hours over four full days.

Each canister connection point in the 1916A is welded to the 1/8” Silonite-coated stainless steel tubing, ensuring a leak-proof system. Additionally, the modules are designed with user convenience in mind, featuring fast and tool-free options for loading and unloading canisters. These options include simple mechanisms that allow canisters to be easily attached or detached with a straightforward “snap” or “twist” motion. This design not only enhances the system’s efficiency but also minimizes the time and effort required for sample collection, making the entire process more streamlined and user-friendly.

Advantages over real time sampling and other canister sampling systems

Two 1916As shown with Entech 2.5L Silonite Canisters.