Comparing SiloniteTM Canisters vs SUMMA & other TO-15 Canisters for Air Monitoring - What's Best?

It was about 30 years ago that the first release of EPA Method TO-14 appeared for monitoring of VOCs in ambient air that specified the use of 6L stainless steel canisters having a special internal “SUMMA” passivation to improve chemical inertness. Although “SUMMA” really refers to the process used to apply a Nickel/Chromium oxide layer to the inside of the canister, the canisters themselves became known as SUMMA canisters. The whole purpose of applying the Ni/Cr Ox layer was to prevent exposure to iron, as iron is known to catalyze the reaction and subsequent loss of several of the VOCs in the TO-14 method list, thereby reducing the effectiveness of the canister as a sampling and storage device. With canister whole air sampling, it’s all about how long the sample can remain in the canister without any of the concentrations changing. The Ni/Cr Ox layer greatly improved the stability of TO-14 compounds in 304 stainless steel canisters relative to uncoated canisters. Considering that 304 stainless is 70% iron, applying something to the internal surface to cover up the iron is really not an option.

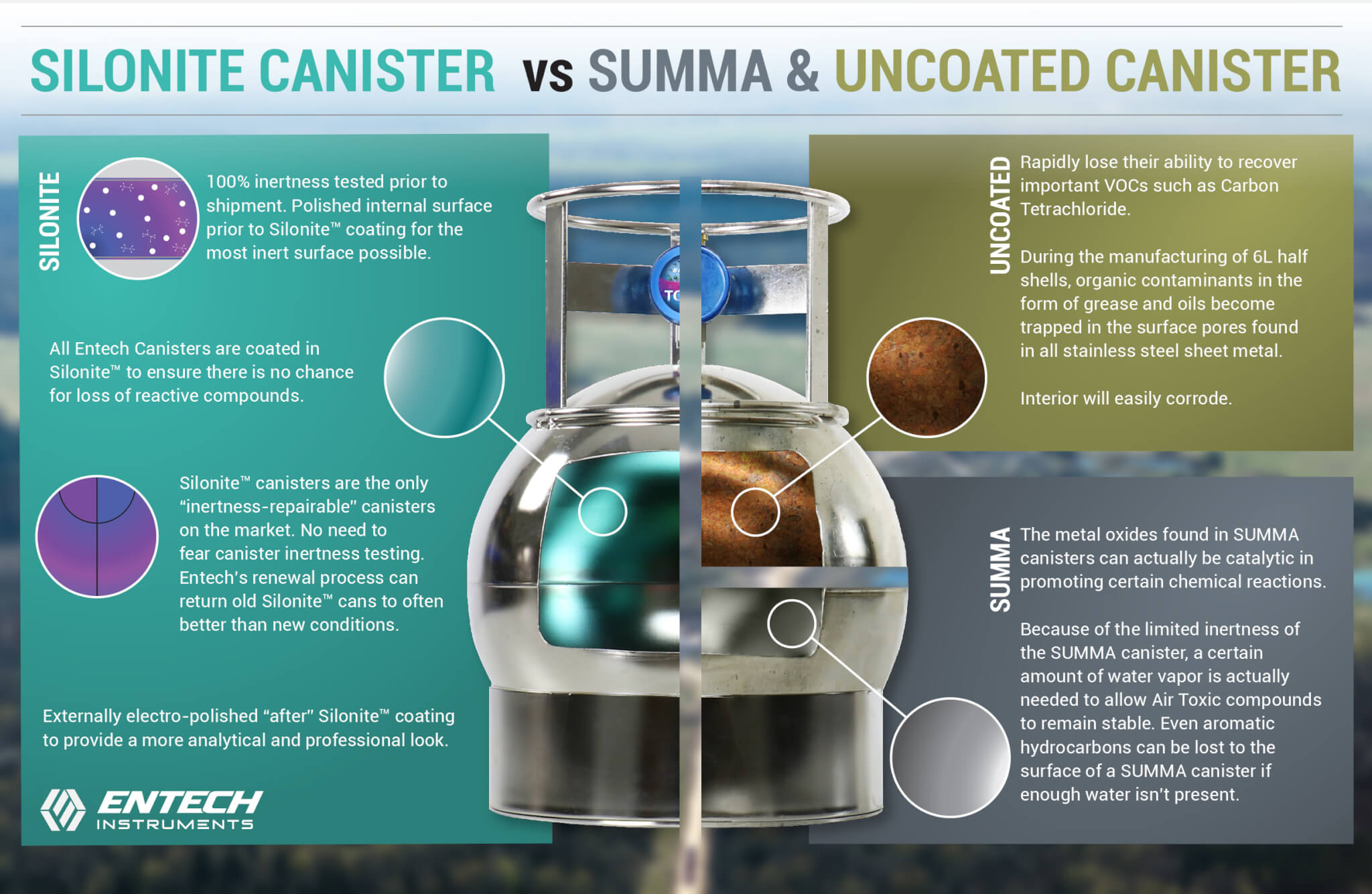

The SUMMA passivation process has some drawbacks. First, although the Ni/Cr Ox layer prevents exposure to iron, it leaves an ionically bound surface that will adsorb polar VOCs and aromatic compounds unless there is enough water vapor in the canister to out-compete these compounds for this somewhat active surface. This works for the compounds on the TO-14 list, but more reactive compounds including reduced sulfurs and amines still exhibit poor stability. Also, it is important to realize that extra water must be added to SUMMA canisters to keep VOCs in the gas phase when performing sampling when relative humidities dip below about 20%. Remember that “percent relative humidity” is temperature dependent. When sampling on a Winter day where the ambient temperature is below 0 deg C, collected canisters will almost certainly be below 20% RH when brought back into a laboratory that is at a more comfortable 25 deg C. In these cases, water should be added to SUMMA canisters “prior” to sampling, by injecting about 50ul into the evacuated 6L canister before deployment to the field. Also, during canister cleaning, it is recommended to fill and evacuate SUMMA canisters a few times at room temperature before heating the canisters, as raising the temperature to 80 deg C will drop the Relative Humidity to just 1-2%, and polar compounds will stick quite effectively to the SUMMA passivated surface, preventing their removal from the canister.

SUMMA Canister manufacturing is also expensive, as it creates extremely toxic chromium waste that requires disposal into specialized landfills. For the past 15 years, deactivation layers consisting of vapor deposited silica have been replacing the SUMMA passivation process, as the silica layer is more inert, requires no water vapor to complete the canister passivation, and produces no toxic waste. The gas phase deposition process also makes for a smoother deposition, relative to the diffusion limited liquid phase SUMMA deposition process. Silonite Canisters have this internal silica layer and have been demonstrated by independent laboratories to be the most inert canister available, based specifically on the recovery of hydrogen sulfide. The silica layer is similar to the inside of a GC column, and Silonite canisters are helping to increase the range of compounds recoverable to approach nearly that of “all GC compatible compounds”. For SVOC range compounds (Semi-Volatiles), Silonite canisters must be heated during analysis to ensure that these heavier compounds are driven quantitatively into the gas phase, just like a GC column needs to be heated to elute heavier injected compounds. Entech has developed laboratory analyzers that automate the heating process, making it possible to extend the range of recoverable compounds from C1-C12, to C1 to over C25.

So the next time someone asks you about SUMMA canisters...

You can tell them that almost all canisters made today are not SUMMA Canisters, but are either Silonite Canisters or some other brand. Please see our complete discussion of canisters in our “Understanding Canisters Technology” document in our Technical Library. Beware of other canisters on the market with “no internal coating at all”. These manufacturers have simply electropolished and nitric acid passivated the 304 stainless, which only removes the iron that is right on the surface. When brand new, these canisters are shown to be inert because initially there is little iron on the very surface after nitric acid stripping during manufacturing. However, as these canisters age, oxidation and corrosion will expose the iron just under the surface, drastically reducing the stability and recovery of extremely carcinogenic compounds such as carbon tetrachloride. Many of these canisters are marketed as “SUMMA-Like”, but they don’t have the actual SUMMA applied NiCrOx surface that is hundreds of atoms thick, preventing the iron well below the surface to ever be exposed, even after 20 years. Finally, “all ceramic” deactivated glass canisters, called Bottle-Vacs, do not have reactive iron to worry about, and have shown recoveries equivalent or superior to those of SUMMA canisters for TO-14A and TO-15 compounds, and these are slowly gaining popularity as a low cost solutions for canister sampling. Bottle-Vacs are also becoming popular for diluting very high concentration canister samples in the laboratory prior to analysis.