Introduction

Stainless steel canisters offer a tremendous advantage over other air sampling media, namely Tedlar® bags and adsorbent traps. When canisters were first introduced, the “SUMMA” passivated canister was the only option available. Today, with the availability of electropolished, silica lined (Silonite™ and others), and glass (Bottle-Vac) canisters, as well as multiple valves and gauges to choose from, air monitoring personnel must be further educated on how to properly choose, clean, evaluate and certify a canister for TO14 and TO15 analysis. This document gives a background overview of different types of canisters as well as the procedure for properly certifying them for use.

Background

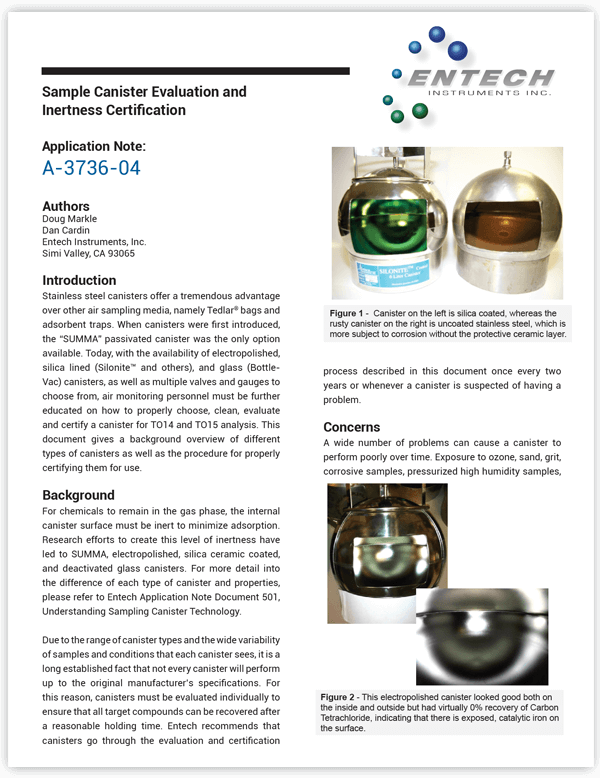

For chemicals to remain in the gas phase, the internal canister surface must be inert to minimize adsorption.

Research efforts to create this level of inertness have led to SUMMA, electropolished, silica ceramic coated, and deactivated glass canisters. For more detail into the difference of each type of canister and properties, please refer to Entech Application Note Document 501, Understanding Sampling Canister Technology.

Due to the range of canister types and the wide variability of samples and conditions that each canister sees, it is a long established fact that not every canister will perform up to the original manufacturer’s specifications. For this reason, canisters must be evaluated individually to ensure that all target compounds can be recovered after a reasonable holding time. Entech recommends that canisters go through the evaluation and certification process described in this document once every two years or whenever a canister is suspected of having a problem.

| File | Action |

|---|---|

| Sample Canister Evaluation and Inertness Certification App Note | Download |

| Version | |

| Total Files | 1 |

| Create Date | August 23, 2015 |

| Last Updated | October 5, 2018 |