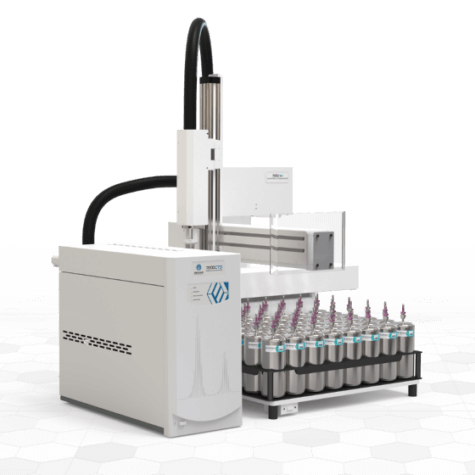

The 7200CTS Preconcentrator and 7650-M MillionAirTM System

The 7200CTS / 7650-M combination, also known as the “MillionAir-CTSTM Analysis System,” is the most advanced instrumentation ever developed for the analysis of volatile and light semi-volatile compounds in air and soil gas. Now, analyze any size canister in your inventory with the quality assurance of direct inlet robotics. The 7650-M includes the “samplesafe” feature that performs rapid screening of samples without exposure to the 7200CTS trapping system, thereby maintaining far superior system hygiene relative to other preconcentration systems.

The MillionAir-CTSTM system gets its name by being able to handle samples with a million fold difference in concentration without pre-dilution. Air labs have always been faced with the dilemma of having to screen potentially high concentration air samples to determine if dilution will be needed, while at the same time preventing the contamination of their analyzer. Rotary valve autosamplers, used by all other manufacturers, expose potentially high concentration samples to inlet lines for hours or even days, creating a background in the system that may take days or even weeks of flushing to eliminate.

Entech Cryogen-Free 7200CTS

Entech is proud to release the world’s first multi-capillary column trapping system (MCCTS – Patent Pending), for the precise concentration of vapor phased volatile chemicals in the boiling point range of -50°C to 230°C without the need for liquid nitrogen or complicated electronic cooling. Evolving from 28 years of continuous improvements and industry feedback on earlier preconcentrators, the 7200CTS is dramatically improving TO15 performance and sample throughput. Many of the important advancements that have led to its unparalleled reproducibility, such as quantitative volumetric measurements utilizing “Accu-Sample Technology,” and digital valve isolation, are left unchanged from its market leading LN2 based 7200A predecessor. The core trapping system, however, has been completely reengineered, giving way to a technology that will likely replace the utilization of packed traps for most, if not all methods requiring the preconcentration of vapor phase volatile organic compounds.

MillionAir-CTS Analysis System Features

Now, analyze all sample types, including Tedlar® bags, canisters, and thermal desorption tubes!

(Tube screening and analysis requires the addition of the 5400B Thermal Transfer System).

Direct Inlet Robotics

New! MCCTS & Cryogen-Free Analysis

SampleSafe Screening

A New Standard of System Hygiene & Uptime

Improved Precision and Sensitivity

Near complete elimination of water!

Quantitative Accuracy

Million Air 6 Minutes Per Injection Screening to Avoid Contamination

New Technologies are Driving Business Model Changes

CTD (Cold Trap Dehydration) systems that utilize packed traps have played a workhorse role in the modern analytical air lab, but technology has evolved and it’s important to highlight the recent achievements of Multi-Capillary Column Trapping technology and the significant impact these systems will have on the economics of air and soil gas laboratories. Here we evaluate the efficiency improvements that come with the latest preconcentration and robotics solution, the MillionAir- CTSTM ; including, faster cycle times, rapid screening for high concentration samples, system sample capacity, and even the shipment savings from the utilization of smaller canisters.

Entech 7200CTS Preconcentrator

Sample Run Efficiency: CTS vs Packed Trap CTD Systems

The cycle times for the LN2 free 7200CTS, from injection to injection, have been improved by as much as 7 minutes over existing CTD systems. The following table highlights the improvements and time savings.

Time Savings Model of 7200CTS vs 7200A & 7100(x)

If we assume even a 5 minute average, then reducing cycle times from 30 to 25 minutes means a savings of 10 minutes per hour. Considering that MillionAir-CTS™ automation enables overnight operation, this equates to 240 minutes saved per day or an extra 9 samples processed.

Benefits

Sample Capacity & Automation

The MillionAir-CTS™ system is designed to take automation to a whole new level by supporting unattended analysis of up to (24) of the all new Entech 2L canisters, a perfect solution for low level TO-15 applications, or up to (48) 450mL/600mL canisters for 24hr automated soil gas analysis. For soil gas, this is a capacity increase of 200% when compared to using traditional canister towers. By utilizing 3 dedicated calibration standard or blank positions, the MillionAir-CTS™ can schedule the QC checks every 20 samples or as needed.

Benefits

Single Inlet Advantages

TO15 laboratories have been increasingly asked to analyze canister samples that are at elevated levels, many of which can be as high as several thousand PPM. Canister towers are not optimally designed to handle higher concentration samples due to their longer transfer lines, cold fittings, and use of rotary valves. Canister towers have significantly more surface area than the single inlet line of the 7650 and this can cause significant carryover if not properly managed. For example, with a (16) position inlet, a high concentration sample in the PPM range placed on one of the positions and left overnight would create a residual background level that is much higher than the other autosampler positions, even after substantial backflushing. With robotic autosamplers, exposure to the sample occurs for only a few minutes while the sample is being drawn into the preconcentrator, then the heated line is immediately flushed with helium or nitrogen to minimize exposure time.

Benefits

Smaller Canisters, Bigger Margins

6L canisters have played an important role in trace level analysis over the last 30 years, but instrumentation has become many times more sensitive over that time and canisters have also become more inert. 2L canisters from Entech offer enough sample volume for five, possibly six analyses, all in a compact form that is cheaper to ship, easier to handle, and more efficient to analyze.

Shipping Comparison: 2L vs 6L UPS Blue Rates

Enjoy Your Hassle-Free and Tool-Free Lab!

Switching to Entech robotics also means you’ll be keeping your

tools in the drawer. Loading the Micro-QT™ equipped Mini-Cans™

into the 7650 robotics tray takes just seconds versus having to manually attach large canisters onto tower autosamplers using wrenches. Using tools both in the field and in the lab introduces the chance of damaging fittings and causing leaks. The Micro-QT is a next generation air and gas valve offering uncompromising leak-tight performance in an ergonomic design. Once the valve is connected to tubing using compression fittings, mating male and female valve ends is literally just a quick “snap”.

Benefits

7200CTS Preconcentrator and 7650-M MillionAirTM System

The MillionAir-CTS system is designed to take automation to a whole new level by supporting unattended analysis of up to (24) of the all new Entech 2L canisters, a perfect solution for low level TO-15 applications, or up to (48) 450mL/600mL canisters for 24hr automated soil gas analysis. For soil gas, this is a capacity increase of 200% when compared to using traditional canister towers. By utilizing an additional 5 positions on the MillionAir-CTS, QC runs can also be run in-line to enable automatic batch certification.