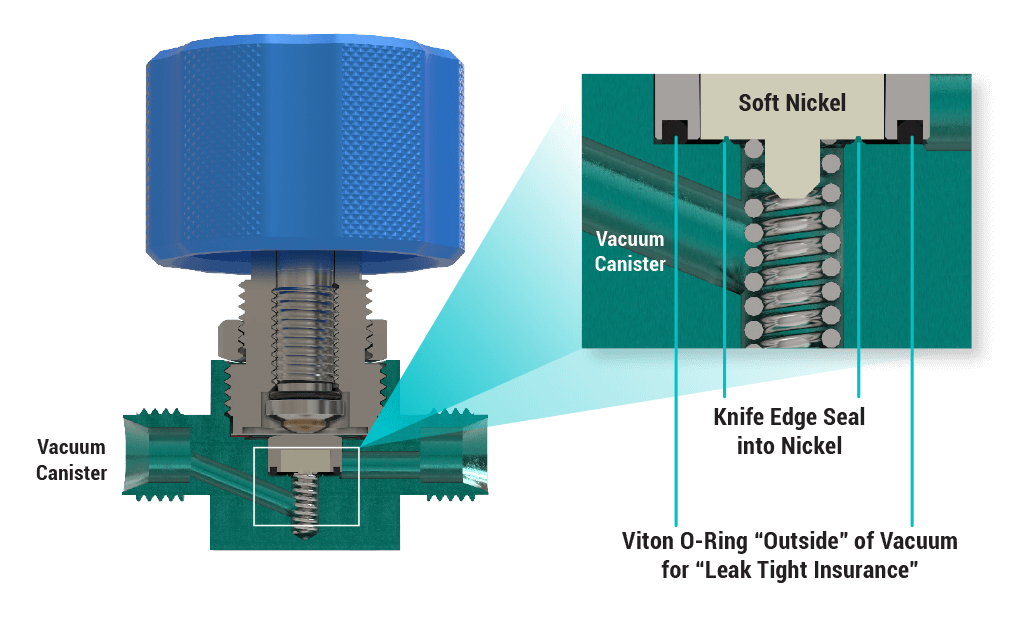

The Only Valve With A Double Seal

With years of feedback from lab customers and field sampling professionals, Entech has engineered a valve that not only seals with less force than any other valve on the market, but also provides a double seal for extra assurance of leak-free operation even in the most demanding conditions. To achieve these goals, the Entech TrueSealTM valve utilizes some key design innovations and distinctions.

<< Watch the video to learn more

A Superior Metal to Metal Seal

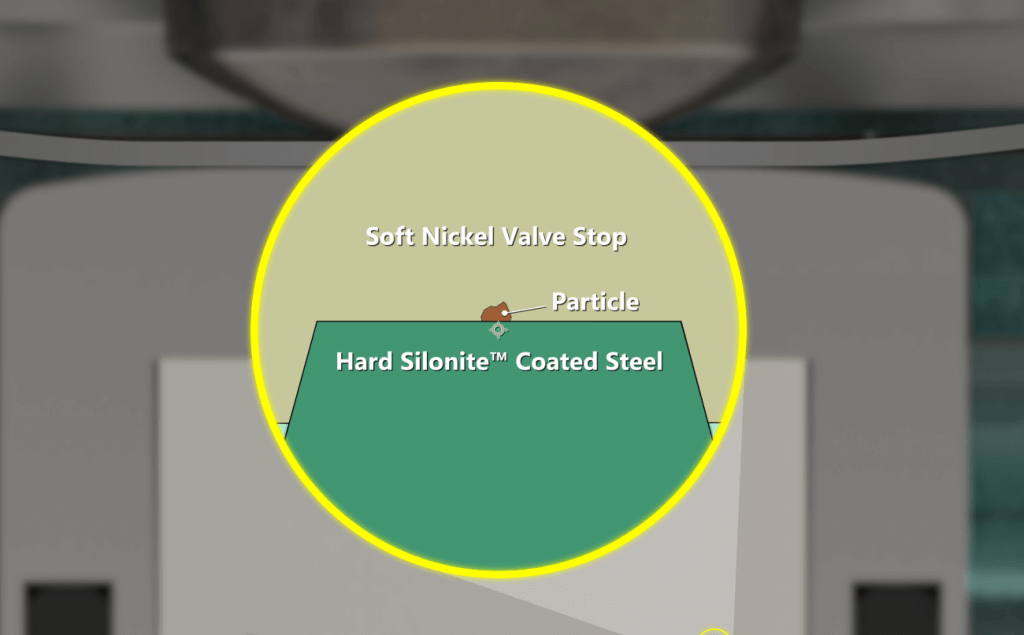

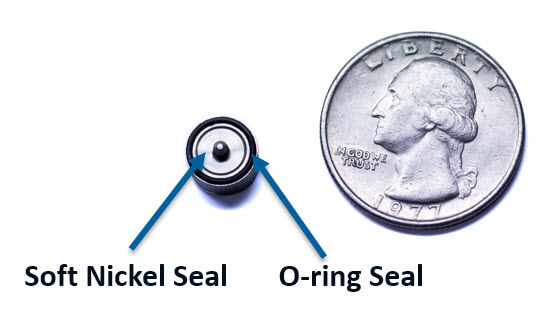

The primary sealing surface is a stainless steel knife-edge which cuts into a softer nickel valve stop. Because the softer nickel valve stop can yield and conform to particles, the two sealing surfaces are able to fully come together even in the event of surface contamination. This primary metal-to-metal seal alone achieves a more reliable long term seal than other valves that utilize highly polished sealing surfaces.

A Double Seal Provides Extra Assurance

Entech wanted to go a step further with the TrueSeal™ valve and completely eliminate any potential for leaks. To achieve this, a small O-Ring was added as a secondary seal. This O-Ring has 15x less viton than the popular Bottle-VacTM, 30x less viton than both of the major flow controllers in use today, and is positioned outside of the influence of the canisters vacuum. It is therefore almost completely isolated from the sample, yet serves as added insurance should the primary mechanism become compromised.

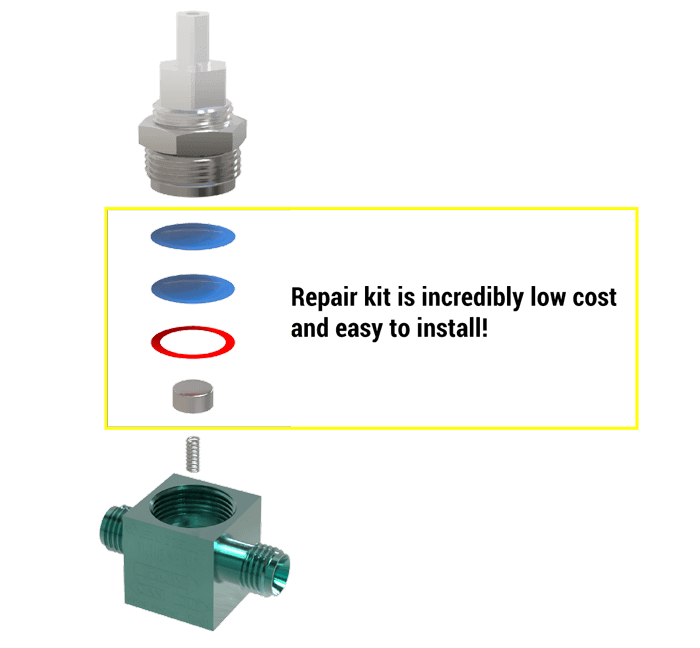

Repairable.

While the TrueSeal™ valve is designed to tolerate particles better than any other valve on the market, there are times when substantial debris accumulates from repeated operation in dirty environments. The repair kit from Entech is incredibly low cost and easy to install, returning your TrueSeal™ valve to like-new condition in just minutes.

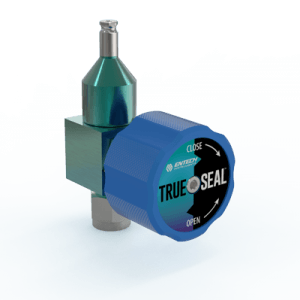

New EasyGrip Knob

If you’re familiar with the TO valves, you’ll quickly notice the new and distinctive EasyGrip knob design. This ergonomic knob provides for a more comfortable experience when processing hundreds of canisters in the lab or having to conduct numerous sampling events in the field. It is designed to contour the hand and provide a more relaxed feel while promoting a more gentle closure. A simple 1/3 turn is all it takes to close.

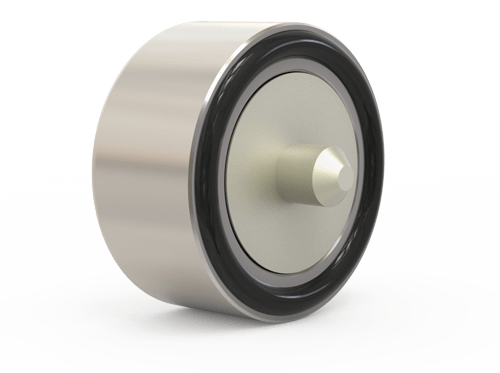

Finger Tightened Cap

Also new on the outside, the TrueSeal valve comes standard with a finger tightened cap that makes a better seal than the alternative brass caps. There is also far less potential for thread damage with the elimination of wrenches. Thread damage is permanent and translates to replacement costs and time. Tool-free operation is just another way Entech protects your product investments.

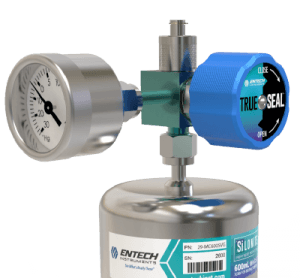

SiloniteTM Coating Comes Standard

All TrueSeal valves will now come standard with the ultra-inert Entech Silonite coating. Silonite prevents the losses of sticky or reactive compounds and provides an inert path from the point of sample introduction to collection.

Classic Male MQT to Tube

The MQT-ST400S is a shortened Silonite Male Micro-QT Valve with tube connection. It can be utilized along with the Entech TrueSeal valve to enable tool-free operation or auto-sampler compatibility of Mini-Cans and classical sampling canisters such as the 2.7L, 3.2L, or 6L canisters..

New! Finger-tightened MQT Adapter!

Tired of dealing with nuts and ferrules? We don’t blame you. Now you can convert your TrueSeal valves to be robotics compatible simply by using a face sealing finger-tightened MQT adapter. Just another time saving innovation that you can expect when investing in Entech products. Click here to request a quote.